More than Power Supplies & EMI/EMC Filters

With more than 60 years of experience as a Power Supply and EMI Filter manufacturer, our team can provide unmatched engineering support to take your product from design to production.

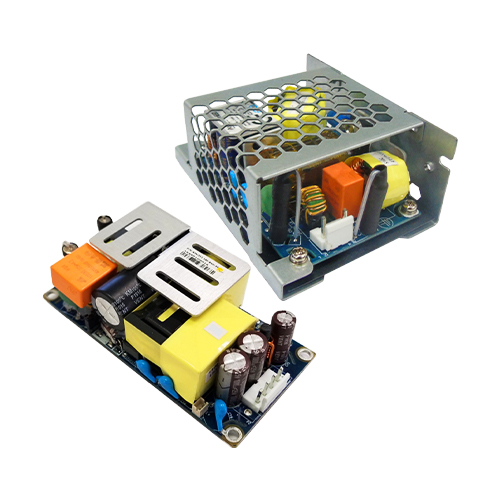

ASM202: Up to 240 Watts of Regulated DC Output Power

The AstrodyneTDI ASM202 series power supplies offer a compact, high-power-density solution for medical and industrial uses, supporting AC and DC inputs. With an input range of 80 to 264 VAC or 120 to 380 VDC, they provide up to 240 Watts of regulated DC power. These units feature a remote on/off for convenience and are designed with a focus on safety and efficiency.

Custom Solutions

A variety of technical requirements can prevent you from finding the perfect off-the-shelf solution. At Astrodyne TDI we have the advanced tools and technology to design and modify power supplies and EMI filters to meet your unique requirements.

Applications

Astrodyne TDI delivers power and EMI filter solutions to a diverse array of markets and industries world-wide.

Astrodyne TDI News and Blog Posts

Blog | Apr 3, 2024

Delivering Accurate and Reliable Power to Electrostatic Chuck Systems

To kick things off, let's explore the vital function that electrostatic chucks serve in the realm of semiconductor manufacturing. These essential components play a key role in securely anchoring ...

Blog | Mar 19, 2024

Understanding Power Requirements for Hydrogen Generation

Hydrogen generation has skyrocketed in recent years as organizations search for viable alternative energy sources to power vehicles, backup power, and more. Although several methods exist to generate ...

BLOG | June 24, 2020

3-Phase Power: Delta vs Wye Explained

Three-phase power plays a key role in the design of electrical systems, and 3-phase EMI filters are an important part of the electrical devices in different markets, primarily in heavy-duty industrial applications.